Recycling

We help utilise the hidden potential of secondary raw materials and give them a second chance. Our solutions protect expensive technologies from damage.

Primary raw materials are becoming increasingly rare. Their mining and processing taxes the environment and costs for waste disposal are rapidly increasing. Thanks to our know-how and innovations, we can offer cutting-edge solutions for magnetic separation and recycling of materials.

By using magnetic separators, we are capable of recovering metals for further use (iron, copper, zinc, aluminium) or removing undesirable metallic particles from the recyclate before further processing (glass, wood, plastics, concrete, paper, biowaste, tyres).

Thus, we aid in limiting the need for mining new raw materials. As a result, we help protect the environment and promote circular economy, while at the same time protecting expensive machinery (crushers, extruders, mills) from damage due to random metal objects.

For wood recycling, we have solutions for separating unwanted metals with different types of magnetic separators from shredded material. Firstly, to protect the technological equipment and secondly to increase the quality of the raw material for further processing, where the requirement is that the raw material is free of any metal parts, screws, nails, etc., which could cause problems during further processing. Read the article on the website of our partner in Poland.

Want to read more? Take a look at the related documents.

Need help? Write us

Related documents

Which Machines Aid in Recycling?

|

Iron Separation and Protection of MachineryOverband magnetic separators separate ferrous objects from communal, demolition and construction waste, electric cables, car tyres, etc. They protect crushers of wood waste, electronic waste (refrigerators, washing machines) or biowaste from damage due to random ferrous objects. Also available in ATEX implementation on request. |

Iron Separation from Loose MaterialsDrum magnetic separators are an excellent solution for separating ferrous particles from large volumes of loose materials, such as when recycling blasting agents, glass, crushed remnants during car wreck recycling, etc. |

|

|

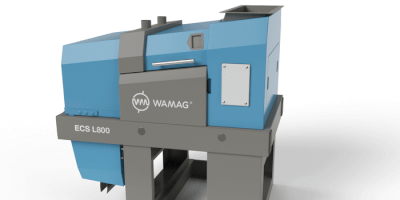

Separation of Non-ferrous MetalsThe eddy current separator separates non-ferrous metals (aluminium, copper, brass) from waste electrical and electronic equipment (WEEE), from slag and ash in waste incinerators, aluminium caps in glass recycling or brass hinges and hitches in wood recycling. |