Magnetic Wet Drum Separator

Removal of ferromagnetic impurities from operating fluids, coolants. Continuous cleaning. Non-stop operation.

Branches: metalworking | automotive

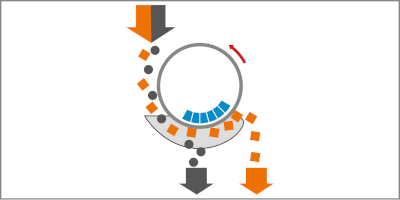

Coolant used during machining of metals (cutting, grinding, turning) will contain ferromagnetic impurities such as dust, chips, scales, rust, shavings and steel fragments after use. How to efficiently remove these impurities and reuse the coolant? Enter WMWD, the WAMAG magnetic wet drum separator.

Its specially designed magnetic system creates a powerful magnetic field that penetrates deep into the layer of liquid and separates ferromagnetic particles from micronic to 2 mm in size.

The WMWD is designed for wet separation and is, therefore, fully stainless. Installing the separator into your line is simple. Cleaning takes place continuously, with necks constantly feeding coolant into the device. The separator is suitable for non-stop operation. Once free of Fe particles, the coolant leaves the drum separator through the outlet neck. More intensive separation of Fe particles from the liquid is ensured by a pressure roller.

The coolant can be reused once any additional impurities are removed. Dispose of tailings in accordance with local regulations on waste. Your business activity thus becomes much more eco-friendly.

We are able to perform simulations on a testing separator and propose a suitable solution for your application.