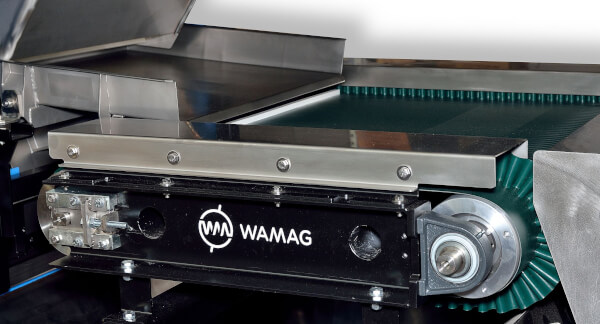

Permanent High Intensity Belt Separator

Removal of ferromagnetic and weakly magnetic impurities (stainless steel) from raw materials or foodstuffs. Product quality control.

Branches: food industry | mineral processing

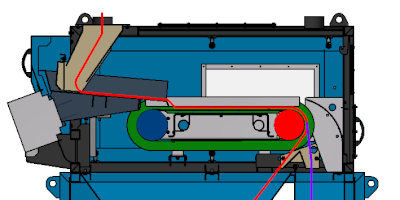

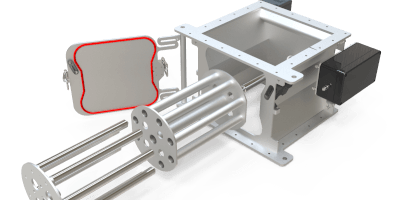

Magnetic separator equipped with vibrating feeder and small belt conveyor with high intensity NdFeB magnetic headroller.

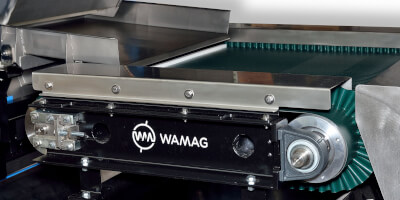

The neodymium headroller with a magnetic induction of 12 000 Gauss on the surface cleans products and raw materials from ferromagnetic and stainless steel impurities. The separator removes particles from 0.1 to 15 mm in size. Safety plexiglas viewing windows, located on the top and sides, allow the separation process to be monitored. The size of the machine is 1900x1660x1455 mm (lxwxh) and the weight is approximately 750 kg.

Particularly in the food industry, it helps to maintain and declare the required quality to customers.

We also produced the PVPS magnetic separator with a belt certified for contact with foodstuffs and at the same time with the modification of the whole machine for use in explosive environments (ATEX version). It comes complete with control box and vibrating feeder.

The permanent high-intensity belt separator can be used for cleaning raw materials, e.g. in the glass industry, in the processing of glass sands, removing iron discolouration, iron oxides or bearing iron from products and other applications.

Contact us for details and consultation of your application.