Iron separation from wooden chips streams in ATEX area

Overband magnetic separators in the explosion-proof version protect wood crushers and prevent accidents by unwanted iron particles.

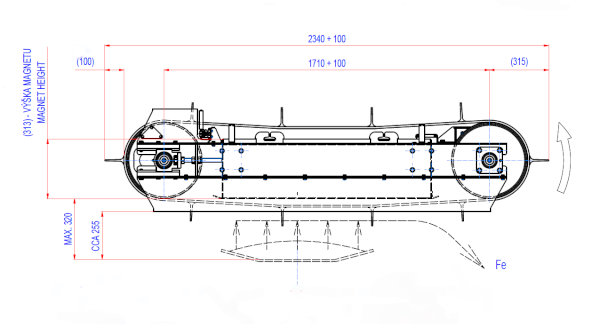

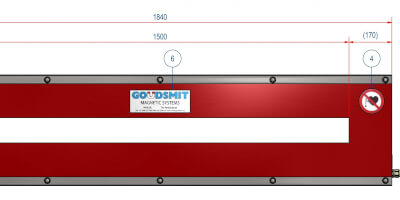

Machine type: ROFC080340_Ex2D – overband magnetic separator permanent

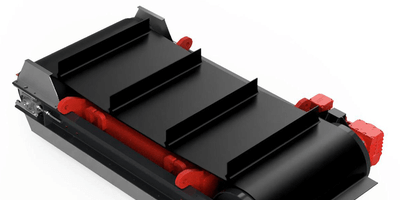

Parameters: dimensions 2,440 × 1,300 × 575 mm, weight 1,520 kg, explosion-proof ATEX version for zone 11/22, degree of protection IP 65, 800 mm wide ribbed belt, ferrite magnet magnetic system

Application:

The magnetic separation of unwanted ferrous particles from wood chip flow is an important technological point. The separator can operate in continuous 24-hour operation. Cleaning of the captured particles is carried out automatically without interrupting the production process using of the belt with cleats that carry the particles away from the conveying flow. The separator is positioned across the material flow. It is equipped with an electric motor with gearbox.

The protection of the crushing equipment against destruction by a random ferromagnetic object is very important. If an accident were to occur in this part of the production line and operations had to be stopped, it would cause a high financial loss to the customer.

To expand the production capacity in the wood processing plant, we have supplied 4 pieces of these overband permanent separators. The magnetic system is made of ferrite magnets. In this case, it was not necessary to take into account the weight and smaller dimensions of the separator as for mobile applications, where a machine with neodymium magnets is chosen for its lower weight and dimensions with the same magnetic field strength.

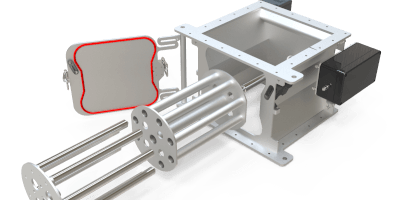

The environment of the woodworking industry is often classified as a dust explosion hazard. We are prepared for this too. We have certified overband separators, both permanent and electromagnetic, and a complete production system for ATEX.

The certificates can be found in the download section. If you have any questions, please contact us.